Essential Guide to Food Production Cooling Systems

Key Takeaways

- Summary of food production cooling systems and their significance

- Varieties of cooling systems utilized in food production

- Essential elements that comprise cooling systems

- Benefits of effective cooling systems in food production

- Factors to consider in the design of cooling systems

- Upkeep requirements for food production cooling systems

Overview of Food Production Cooling Systems

Food production cooling systems play a crucial role in maintaining the safety and quality of chilled food and frozen foods throughout the stages of food processing. These systems from Summit Process Cooling utilise various techniques, including adiabatic cooling and free cooling, to efficiently manage cooling and heating demands. Effective temperature control is essential for preserving food products, extending their shelf life, and preventing spoilage. In a commercial context, the selection and design of food production cooling systems directly impact energy efficiency and operational costs, making it imperative for food producers to invest in modern solutions. Understanding the intricacies of these systems helps ensure optimal storage conditions and compliance with safety regulations.

Importance of Cooling in Food Safety

Effective temperature control is vital in food production cooling systems to maintain food safety. Rising temperatures can lead to bacterial growth, posing significant risks within the food industry. Evaporative cooling and air-cooled systems play crucial roles in heat dissipation, ensuring that food products remain at safe temperatures. Implementing these systems allows for efficient heat exchange, reducing the likelihood of food spoilage and ensuring compliance with safety standards.

Adopting appropriate cooling methods significantly impacts the overall quality of food produced. Insufficient cooling can result in water heating, which may compromise the texture and flavour of food items. By emphasising the importance of adequate cooling techniques, businesses within the food industry can safeguard their products and build consumer trust. Ultimately, robust food production cooling systems not only enhance food safety but also contribute to the longevity of products in the market.

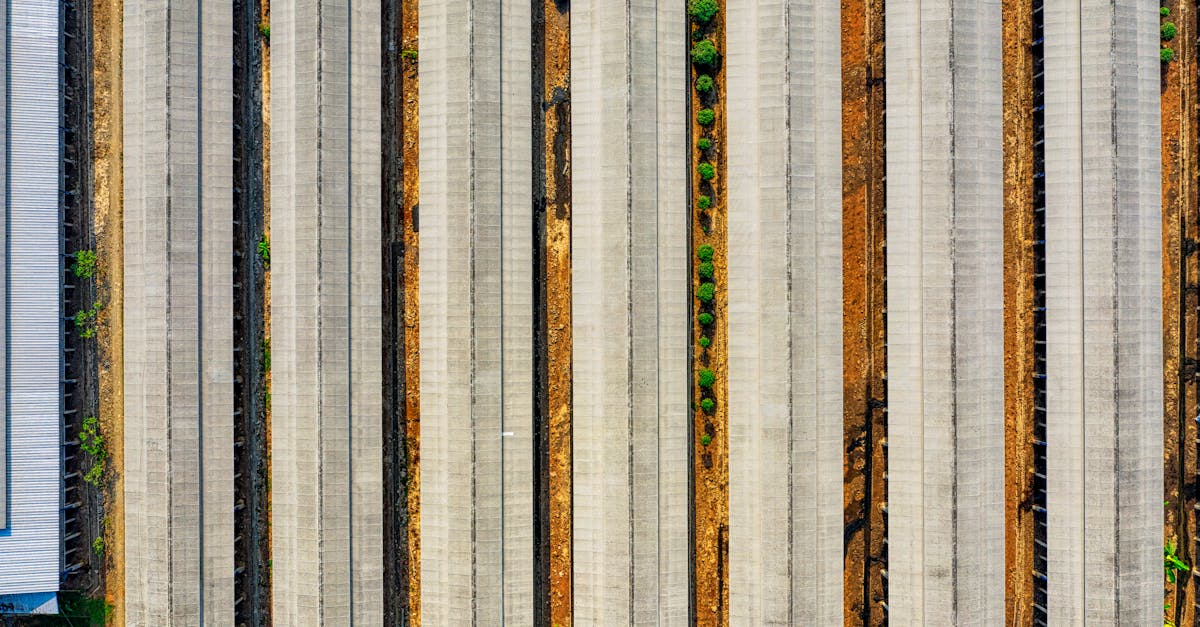

Types of Cooling Systems Used in Food Production

Food production cooling systems play a vital role in ensuring the safety and quality of food and beverage products. Cooling towers are commonly employed within these systems to dissipate heat, allowing chilled water to circulate efficiently. This process is essential for maintaining optimal temperatures in cold storage facilities, especially for perishable items like ready meals. The design and operation of these cooling systems are crucial for preventing spoilage and extending the shelf life of food products.

Heat recovery and heat pumps are integral components of modern cooling systems in food production. These technologies enhance energy efficiency by repurposing waste heat generated during refrigeration processes. The use of a cooling tower in conjunction with a heat pump can significantly improve temperature control and reduce operational costs. As industries increasingly focus on sustainability, integrating advanced cooling solutions has become a priority for both economic and environmental reasons.

- Ensures compliance with food safety regulations

- Reduces energy consumption through efficient designs

- Enhances product quality by maintaining consistent temperatures

- Minimises food spoilage and waste

- Promotes sustainability through heat recovery methods

- Supports the cold chain logistics in food distribution

- Facilitates the production of a wider range of food products

Types of Cooling Systems

Food production cooling systems play a crucial role in maintaining the quality and safety of various foods. These systems can be broadly classified into passive cooling systems and active cooling systems. Passive cooling systems rely on natural processes to regulate temperature, making them suitable for certain applications but less effective in extreme heat. In contrast, active cooling systems, which include refrigeration systems and air conditioning systems, provide precise control over temperatures necessary for preserving items like baked goods and for safely handling ingredients before cooking, frying, or freezing. By effectively managing ambient temperature, these systems ensure that food products maintain their integrity and shelf life, ultimately benefiting both producers and consumers.

Passive Cooling Systems

Passive cooling systems utilise natural processes to regulate temperature within food production environments. These systems are particularly beneficial in settings like bakeries and cheese production facilities, where the quality of food can be directly influenced by temperature and humidity levels. Air conditioning is not always necessary, as passive methods can effectively maintain optimal conditions while significantly reducing energy consumption. The integration of proper design, such as good airflow and thermal mass, ensures that these systems can manage the internal climate without relying heavily on mechanical cooling.

Humidity control is another vital aspect of passive cooling systems, especially in the beverage industry where flavour profiles and product integrity are crucial. Cooling systems can harness ambient conditions to maintain an ideal environment for various products, thereby enhancing overall product quality. Such approaches often involve using specially designed condensers and insulation materials to optimise performance. By leveraging the surrounding environment, food production cooling systems can achieve effective cooling while minimising energy consumption, contributing to sustainability and lower operational costs.

Active Cooling Systems

Active cooling systems play a vital role in modern food production cooling systems, ensuring that temperature-sensitive products are maintained at safe levels. These systems often incorporate complex technologies that allow for precise temperature control, tailored to specific cooling needs. Unlike traditional cooling systems, which rely on passive methods, these advanced systems actively regulate the temperature within a manufacturing area. This capability is essential for perishable goods, as it helps to prevent spoilage and maintain quality throughout the food supply chain.

The implementation of a new cooling system can significantly enhance operational efficiency in food production settings. By utilising bespoke manufacturing cooling solutions, facilities can respond effectively to varying cooling demands, thereby optimising the performance of their cooling systems. Active cooling approaches often feature mechanisms such as refrigeration units and fans, which circulate chilled air, providing reliable cooling. With such systems, food production cooling systems not only extend the shelf life of products but also contribute to overall food safety and compliance with health regulations.

Key Components of Cooling Systems

Effective food production cooling systems rely on key components that ensure optimal cooling and adhere to precise cooling parameters. A reliable cooling system incorporates refrigeration units and insulation materials that work harmoniously to achieve rapid cooling and maintain consistent temperatures. For large batch cooling, cooling plants must be designed to accommodate significant volumes while ensuring energy efficiency. The incorporation of advanced technologies, such as adiabatic cooling systems, provides a perfect cooling solution tailored to the demands of the food production industry. Properly designed cooling plants contribute to food safety by extending the shelf life of products and maintaining the quality of perishable items.

Refrigeration Units

Refrigeration units serve as the backbone of food production cooling systems, ensuring that the temperature of products remains stable and within safe limits. These units operate through a cooling cycle, which often employs technologies such as the evaporative cooling system. Such systems are particularly useful in large-scale food production environments, where maintaining product temperature is critical for food safety and quality. Innovations like summit process cooling and green cooling have been integrated into modern refrigeration units to enhance efficiency and reduce environmental impact within food manufacturing facilities.

The design of refrigeration units must allow for a free-cooling function, utilising ambient conditions to minimise energy consumption. This aspect is vital in optimising food industry processes, allowing facilities to maintain precise control over their cooling needs. Utilising efficient refrigeration units can significantly extend the shelf life of perishable goods, ultimately benefitting both producers and consumers. By investing in high-quality refrigeration systems, food production cooling systems can achieve superior performance, which is essential in today’s competitive market.

Insulation Materials

Effective insulation materials are crucial for maintaining the efficiency of food production cooling systems. These materials help in minimising heat transfer, which is essential for moisture cooling and maintaining the desired temperature for food spec air. High-quality insulation contributes to the optimal performance of cooled chillers and contact cooling equipment, ensuring that food processing needs are met. Proper insulation not only enhances the reliability of temperature control systems but also aids in the effectiveness of adiabatic cooling units in various food processing applications.

The choice of insulation material significantly impacts the energy consumption and operational cost of food production cooling systems. Insulated structures reduce the heat load on cooling units, which optimises the performance of neu cooling technologies. Effective insulation helps in achieving more efficient pull-through cooling, benefiting the entire cooling process. By ensuring that optimal conditions are maintained, proper insulation plays a vital role in extending the lifecycle of cooling equipment while meeting stringent food safety standards.

Advantages of Efficient Cooling Systems

Efficient food production cooling systems play a crucial role in enhancing food quality and ensuring safety within the food industry. Commercial food manufacturers benefit significantly from these systems, particularly in custom food processing where precise temperature control is vital. Utilising coolers and adiabatic coolers helps maintain the integrity of products by delivering cooled air that preserves freshness. Neu cooling brings in 100% fresh air, contributing to optimal environmental conditions for stored goods. By implementing effective cooling strategies, food manufacturers can extend the shelf life of their products, which ultimately supports better inventory management and reduces waste. Such efficiencies not only meet regulatory standards but also enhance overall food industry safety, making efficient cooling systems an indispensable component of modern food production.

Extended Shelf Life of Products

Efficient food production cooling systems play a crucial role in extending the shelf life of various products. With proper temperature management, items such as dairy products and cooked meals can remain safe for consumption over an extended period. Systems like dcn cook chill and evaporative panel coolers ensure consistent temperature control, which is essential for adhering to stringent food safety regulations. In specialist food production environments, such as yogurt production, maintaining a friendly temperature environment is vital for both quality and longevity.

Understanding the relationship between cooling systems and shelf life is fundamental for food manufacturers. Industrial refrigeration systems, paired with cook chill bags, provide the necessary conditions to minimise spoilage and maintain product integrity. Constant monitoring and adjustment of temperatures within these systems can significantly reduce waste and enhance the overall efficiency of food production. Through these methods, producers can ensure that their products are not only compliant with food safety standards but also market-ready for longer durations.

Energy Efficiency and Cost Savings

Efficient food production cooling systems play a crucial role in reducing operational costs for businesses. By implementing chiller systems that ensure precise temperature control, production facilities can maintain optimal coolant temperatures while minimising energy consumption. This level of efficiency is especially vital in cold storage facilities, where maintaining a consistent environment not only preserves product quality but also aligns with strict food safety standards. The ability to reduce temperature effectively enhances the overall performance of the facility, leading to significant savings over time.

Heat recovery opportunities within food production cooling systems present another avenue for cost savings. For instance, beverage production sites can utilise waste heat from refrigeration units to warm other areas of the facility or to assist in other production processes. This dual-purpose approach not only optimises energy usage but also contributes to a more sustainable operational model. By investing in innovative cooling technology, businesses can achieve significant reductions in energy costs while enhancing their production capabilities.

Design Considerations for Cooling Systems

Effective design of food production cooling systems is crucial for maintaining temperature stability and ensuring food safety. Specific temperature requirements must be met, especially in post-cooking scenarios where new heat dissipation occurs. High-capacity refrigeration systems play a vital role in managing the cooling needs of diverse ingredients while aligning with production requirements. Optimising these systems not only enhances production efficiency but also supports potable water production in the food sector. Industrial refrigeration solutions must consider both the scale of operations and the specific needs of the food production cooling systems to deliver optimal results.

System Capacity and Size

Determining the appropriate system capacity for food production cooling systems is crucial for maintaining the correct temperature throughout various industrial processes. Oversized units can lead to inefficient operation and increased energy costs, while undersized units may fail to keep up with the demands of the production line. Incorporating grp cooling towers with a heat recovery option can optimise cooling efficiency and support production workflows while ensuring that product moisture levels are adequately managed.

Choosing the right size of industrial refrigeration units directly impacts the effectiveness of food production cooling systems. A well-sized system not only accommodates fluctuating production volumes but also helps mitigate risks of mold temperature issues. This careful balance enhances overall product quality and safety, proving essential in a competitive market where precision in cooling can define the success of food production.

Temperature Control Mechanisms

Strict temperature control is crucial for food production cooling systems to ensure the safety and quality of products. Static coolers play a vital role in maintaining optimal conditions within production areas, where fluctuations can adversely affect food integrity. An efficient refrigeration system, such as high-efficiency refrigeration units, is essential for regulating temperature while managing humidity process conditions. Custom refrigeration systems are often designed to meet the specific needs of various food types, enhancing the overall effectiveness of the cooling process.

Effective temperature control mechanisms contribute significantly to the performance of food production cooling systems across industries including beverage factories. The heat exchange surface or coil must be carefully designed to accommodate the required cooling loads, promoting seamless temperature regulation. Maintaining strict temperature control safeguards food against spoilage and extends shelf life, making it an integral part of any modern food production operation. Proper management of these systems not only guarantees product safety but also supports adherence to industry standards and regulations.

- Regular maintenance of cooling systems is essential to prevent breakdowns and ensure efficiency.

- Utilising temperature monitoring technology can provide real-time data and alerts for temperature deviations.

- Investing in energy-efficient refrigeration options can reduce operational costs and environmental impact.

- Staff training on temperature control protocols can greatly improve handling practices and safety.

- Implementing backup systems can ensure continuity of cooling in the event of a primary system failure.

- Regular audits and assessments of cooling systems help identify potential areas for improvement.

- Compliance with local food safety regulations is critical for maintaining quality standards in food production.

Maintenance of Food Production Cooling Systems

Regular maintenance of food production cooling systems is crucial to ensure optimal performance and safety. Without proper care, systems may face issues that lead to production stops, jeopardising the freshness and quality of meals. High ambient air temperature can exacerbate these problems, stressing the equipment and increasing specific energy consumption. Regular routine checks can help identify any anomalies in the mains supply or insulation integrity, preventing high temperature differential that negatively impacts food safety. For commercial kitchens, an efficient cooling system directly influences customer satisfaction and energy costs, making it essential to maintain these systems diligently. Keeping the cooling units in top condition not only prolongs their lifespan but also supports the broader packaging market by ensuring that products remain safe and appealing for consumers.

Routine Checks and Repairs

Regular inspections of food production cooling systems are essential for maintaining the integrity of foods and beverage products. During extreme heat periods, these systems must consistently maintain a constant temperature to ensure quality. If a fault occurs, it can disrupt busy production lines and lead to spoilage. Implementing a scheduled routine check not only identifies potential issues but also guarantees that advanced refrigeration technology operates efficiently.

Repairs on cooling systems should be executed promptly to minimise downtime and protect perishable items. Eco-friendly systems often require unique servicing techniques to maintain their efficiency, especially in applications like blast freezing. Regular maintenance helps prevent breakdowns that could compromise product safety and aligns with best practices in food production cooling systems management. Prioritising these checks ensures that the right recipe for operational success is followed in maintaining optimal conditions for food storage and processing.

Importance of Hygiene and Cleanliness

Hygiene and cleanliness are crucial in food production cooling systems to ensure the safety and quality of products. In the beverage industry, where freshness and taste are paramount, a brand-new system must be meticulously maintained. Regular cleaning of refrigeration units and evaporative condensers prevents contamination and ensures optimal performance. Tailored refrigeration solutions can only be effective if they are backed by strict hygiene standards. Neglecting cleanliness can lead to spoilage, affecting frozen goods and the integrity of recipes.

Maintaining high hygiene standards within manufacturing environments directly influences the efficiency of food production cooling systems. Routine sanitation of refrigeration units not only minimises the risk of bacterial growth but also enhances the lifespan of the equipment. Effective maintenance practices extend to all components, ensuring that tailored refrigeration solutions deliver consistent performance. Clean and well-kept systems contribute significantly to product quality and safety, reinforcing industry standards and customer trust.

Conclusion

Understanding food production cooling systems is vital for maintaining food safety and quality. Properly designed cooling systems help to chill products rapidly, reducing the risk of spoilage and ensuring that food remains safe for consumption. Knowledge of various cooling processes is essential for food producers, especially when utilising equipment like bratt pans, which can influence cooking and cooling times. Effective management of these systems not only extends the shelf life of products but also optimises overall efficiency within the food production process. Recipe knowledge combined with an awareness of system capabilities leads to better outcomes in food safety and quality assurance.

- Home

- Top Reads

- Roundup of Innovative Approaches to Cost-Benefit Analysis in Cooling Technologies

- A Review of Top Energy Efficient Cooling Systems for the Food Industry

- Historical Trends in the Cost-Benefit Analysis of Food Production Cooling

- 7 Key Factors Influencing Cost-Benefit Outcomes in Energy Efficient Cooling

- Why Investing in Energy Efficient Cooling Technologies Can Reduce Operational Costs

- Why Understanding the Financial Benefits of Energy Efficient Systems is Crucial

- How to Evaluate the Cost-Effectiveness of Energy Efficient Cooling Systems in Food Production

- What to Look for in Energy Efficient Refrigeration Solutions for Food Safety

- What to Consider When Conducting a Cost-Benefit Analysis for Cooling Technologies

- How to Implement Energy Recovery Systems for Maximum Cost Savings in Cooling

- Roundup of Best Practices for Renewable Energy Integration in Cooling Systems

- 10 Innovative Renewable Energy Solutions for Efficient Cooling

- Why Investing in Renewable Energy Cooling Solutions Makes Economic Sense

- Historical Perspectives on Renewable Energy in Food Cooling Systems

- Review of Renewable Energy Technologies in the Food Industry

- Why Renewable Energy is Essential for Sustainable Food Production

- What to Consider When Using Biomass for Cooling Solutions

- What to Know About Integrating Geothermal Energy in Refrigeration

- How to Optimise Energy Use in Refrigeration with Wind Energy

- How to Incorporate Solar Power in Food Cooling Systems

- Roundup of Best Practices for Insulation in Energy Efficient Systems

- 10 Innovative Insulation Techniques for Energy Efficient Cooling

- A Review of Insulation Materials in Food Production Cooling Systems

- Historical Developments in Insulation Techniques for Cooling Systems

- Why Insulation is Key to Energy Efficient Food Production

- Why Choose Insulation Over Other Energy Saving Methods

- What Insulation Techniques are Most Effective for Refrigerated Transport

- What are the Benefits of Advanced Insulation Materials in Cooling Systems

- How to Improve Energy Efficiency with Proper Insulation Techniques

- How to Choose the Right Insulation for Your Cooling Systems

- Roundup of top energy efficiency practices in cooling systems

- Review of the best energy recovery systems for cooling applications

- 10 innovative energy recovery methods for food production cooling

- Historical advancements in energy recovery systems for refrigeration

- Why businesses should invest in energy recovery solutions for cooling

- Why energy recovery systems are crucial for sustainable food cooling

- What to consider when implementing energy recovery technologies

- Roundup of Cutting-Edge Innovations in Food Cooling Technologies

- How to maximise energy recovery in refrigeration units

- What is the role of energy recovery systems in cooling food production

- How to enhance energy efficiency in food production cooling systems

- A Review of the Latest Innovations in Cooling Systems

- 10 Innovative Cooling Technologies Revolutionising Food Production

- Why Innovative Cooling Technologies Matter for Food Safety

- The Historical Development of Cooling Technologies in Food Production

- Why Energy Efficient Cooling Systems are Crucial for Sustainability

- What to Consider When Choosing Innovative Cooling Options

- What are the Benefits of Innovative Cooling Technologies in Food Processing

- How to Enhance Energy Efficiency with New Cooling Solutions

- How to Implement Innovative Cooling Technologies in Food Production

- Roundup of Best Practices for Integration of Temperature Control in Food Processing

- Review of Modern Temperature Control Technologies in Food Production

- 10 Key Advantages of Integrated Temperature Control Systems in Food Processing

- Historical Development of Temperature Control in Food Processing

- Why Adequate Temperature Management Benefits Food Quality

- Why Integration of Temperature Control is Crucial for Food Safety

- What to Consider When Designing Temperature Control Systems for Food Production

- What is Integrated Temperature Control in Food Processing

- How to Evaluate the Effectiveness of Temperature Control Systems in Food Processing

- How to Implement Integrated Temperature Control in Food Processing

- How to assess the effectiveness of cooling systems in food production

- Roundup of the top advanced cooling techniques for fresh produce

- Review of eco-friendly cooling solutions for the food sector

- History of advanced cooling techniques in the food industry

- Why integrating technology in cooling systems improves efficiency

- Why advanced cooling methods are essential for maintaining food quality

- What are the benefits of using advanced cooling techniques in food storage

- What are the latest advancements in cooling technology for food preservation

- How to implement advanced cooling techniques in food production

- How to optimise cooling systems for perishable goods

- Roundup of Innovations in Temperature Monitoring Technologies

- Historical Overview of Temperature Monitoring Technologies in Food Production

- Five Key Features of Effective Temperature Monitoring Systems

- Review of Top Temperature Monitoring Solutions for Food Industry

- Why Investing in Advanced Temperature Sensors Can Improve Efficiency

- Why Temperature Monitoring is Crucial for Food Quality Assurance

- What to Consider When Evaluating Temperature Monitoring Solutions

- What to Know About Real-Time Temperature Monitoring in Food Safety

- Roundup of Innovative Passive Temperature Control Methods for Food Storage

- 7 Key Advantages of Using Passive Temperature Control in Food Safety

- How to Choose the Right Temperature Monitoring Technology for Your Needs

- How to Implement Temperature Monitoring Systems in Food Production

- Review of Eco-Friendly Materials for Passive Cooling Applications

- Historical Overview of Passive Cooling Techniques in Agriculture

- Why Passive Cooling Solutions are Essential for Sustainable Food Systems

- Why Choose Passive Temperature Control for Long-Term Food Preservation

- What is the Role of Insulation in Passive Temperature Control

- What are the Benefits of Passive Temperature Control Methods in Food Production

- How to Implement Passive Cooling Techniques in Food Storage

- How to Enhance Food Freshness with Passive Temperature Control

- Review of Leading Active Cooling Solutions for Food Production

- Why Businesses Should Invest in Active Cooling Solutions

- Roundup of Best Practices for Active Temperature Control in Food Industries

- Historical Development of Active Temperature Control in Food Systems

- 7 Key Facts About Active Temperature Control Technologies

- What to Evaluate in Active Temperature Control Systems for Food Safety

- Why Active Temperature Control is Essential for Food Preservation

- What to Consider When Choosing Active Temperature Control Methods

- How to Optimise Active Cooling Systems for Perishable Goods

- How to Implement Active Temperature Control in Food Production

- Roundup of Innovative Refrigeration Solutions Transforming the Food Industry

- Review of the Latest Innovations in Refrigeration for Food Preservation

- 10 Trends in Innovative Refrigeration Technologies to Watch

- Historical Development of Refrigeration Technologies in Food Production

- Why Businesses Should Invest in Modern Refrigeration Solutions

- Why Innovative Refrigeration Technologies Are Essential for Reducing Food Waste

- What to Consider When Upgrading Your Refrigeration Systems

- What to Know About Emerging Technologies in Food Refrigeration

- How to Implement a Sustainable Refrigeration Solution in Your Business

- How to Choose the Best Innovative Refrigeration Technology for Your Food Production Needs

- Roundup of Best Practices for Refrigerated Transport in the Food Sector

- Review of Refrigeration Systems for Transporting Fresh Produce

- Top 10 Innovations in Refrigerated Transport Technology

- Historical Overview of Refrigerated Transport in Food Distribution

- Why Temperature Control Matters in Refrigerated Transport

- What to Consider When Implementing Refrigerated Transport Systems

- What are the Advantages of Using Refrigerated Transport in the Food Industry

- Why Efficient Refrigerated Transport is Crucial for Food Safety

- How to Choose the Right Refrigerated Transport Solution for Your Business

- How to Optimise Refrigerated Transport for Perishable Goods

- Roundup of the top cryogenic cooling solutions in the market

- Review of the latest cryogenic equipment for food safety

- 10 benefits of using cryogenic cooling in food production

- Historical advances in cryogenic cooling systems for food storage

- Why businesses are investing in cryogenic refrigeration technologies

- What is cryogenic cooling and its significance in food production

- How to implement cryogenic technology in food processing

- Why is cryogenic cooling vital for modern food industries

- What to consider when choosing cryogenic systems for food applications

- How to optimise cryogenic cooling for food preservation

- Roundup of top absorption refrigeration solutions for perishable goods

- Review of the latest absorption refrigeration systems for commercial kitchens

- 7 innovative applications of absorption refrigeration in food production

- A historical overview of absorption refrigeration technology in food industry

- Why choosing absorption refrigeration systems can reduce operational costs

- Why absorption refrigeration is favourable for sustainable food production

- What are the benefits of absorption refrigeration in food preservation

- What to consider when implementing absorption refrigeration in food processing

- How to improve energy efficiency in absorption refrigeration

- Review of top vapour compression refrigeration units for the food industry

- How to optimise absorption refrigeration systems for food production

- Roundup of best practices in vapour compression refrigeration

- 10 amazing innovations in vapour compression refrigeration

- Why choose vapour compression refrigeration for perishable goods

- Historical developments in vapour compression refrigeration technology

- Why vapour compression systems are crucial for food safety

- What are the benefits of vapour compression refrigeration in food storage

- How to optimise vapour compression refrigeration for food production

- What to consider when designing vapour compression refrigeration systems

- How to maintain vapour compression systems in food refrigeration

FAQS

How can air cooled cooling systems in a food manufacturing facility help reduce energy consumption in the production area cooling?

Implementing air cooled systems in your food production facility can significantly reduce energy consumption by employing high efficiency refrigeration. These systems are designed to manage temperature more precisely, ensuring that high temperatures do not impact the quality of food products. Moreover, pull-through cooling brings fresh air into the cooling system, allowing for effective heat exchange over surface coils. This not only reduces temperature effectively but also helps in keeping energy costs low for customers, making it a friendly temperature management solution for any industrial air setup.

What are the advantages of using a cooling system in a food manufacturing facility for maintaining food production precise temperatures during high temperatures impacts?

Implementing a cooling system in a food manufacturing facility is essential for ensuring that production area cooling is maintained at optimal levels. This helps to mitigate high temperatures impacts that can occur during the food production process. A well-designed system effectively utilises pressurised water temperature for efficient heat exchange surface/coil operations, which subsequently reduces customers' energy costs by lowering the overall energy consumption associated with cooling.

How does a cooling system in food production help maintain precise temperatures and reduce energy costs for customers?

A cooling system in food production is essential for maintaining precise temperatures, which is crucial for ensuring product quality and safety. By utilising efficient technology, such as pressurized water temperature controls, these cooling systems help reduce energy costs for customers. This ensures that food products remain at optimal temperatures, thereby enhancing productivity and lowering overall operational expenses.

How does implementing a cooling system in food production affect energy costs for customers while ensuring precise temperature maintenance?

Implementing a cooling system in food production not only helps maintain food production precise temperatures but also aids in reducing energy costs for customers. By efficiently managing the temperature within the production area, a cooling system food can significantly lower energy consumption, leading to cost savings and improved product quality.

What are the benefits of cooling systems in food production for customers regarding energy costs?

The benefits of cooling systems in food production for customers include significant reductions in energy costs, as these systems are designed to efficiently maintain optimal temperatures, resulting in lower overall energy consumption during operations. This not only contributes to improved product quality but also ensures cost savings for customers.

What are the potential impacts of upgrading cooling systems for customers in terms of energy costs associated with food production?

Upgrading cooling systems in food production can significantly lower energy costs for customers by improving efficiency and reducing waste. Enhanced cooling technology ensures optimal temperature control, which not only maintains product quality but also decreases overall energy consumption during production. This leads to potential savings on energy bills for customers, making it a financially beneficial investment.

How do cooling systems in food production enable customers to manage energy costs effectively?

Cooling systems in food production play a crucial role in enabling customers to manage energy costs effectively by improving the efficiency of temperature control, which directly impacts energy consumption. By ensuring optimal operation of these cooling systems, customers can achieve significant savings on energy costs while maintaining the quality and safety of food products.

How can food production cooling systems impact customers in terms of energy costs?

Food production cooling systems play a significant role in helping customers manage their energy costs. By maintaining optimal temperatures, these systems reduce the need for excess power usage, leading to lower energy expenses. This efficiency not only benefits the customers financially but also supports sustainability in food production practices.

How do food production cooling systems address the needs of customers while managing energy costs?

Food production cooling systems are essential for customers as they help in maintaining the quality and safety of products while also managing energy costs. By optimising temperature levels, these systems reduce the risk of spoilage and waste, which indirectly results in lower energy costs for customers. Additionally, efficient cooling technologies can significantly lower overall energy consumption, further benefiting customers in terms of financial savings.

How do food production cooling systems influence the overall energy costs related to customer satisfaction?

Food production cooling systems play a significant role in influencing energy costs by enhancing operational efficiency, which in turn benefits customers. By implementing effective cooling solutions, food manufacturers can lower their energy consumption, leading to reduced energy costs. This not only helps in keeping the production costs down but also ensures that customers receive products at a competitive price while maintaining high standards of quality.